Introduction

Companies are expanding synergies through various forms of collaboration with adjacent industries. As a result, shared growth with business partners via the management of sustainable supply chain is becoming more important.

Through our efforts and responsibilities for cohabitation between large and small enterprises, we will continue to control risks in the value chain and build a strong ecosystem for the industry.

Through our efforts and responsibilities for cohabitation between large and small enterprises, we will continue to control risks in the value chain and build a strong ecosystem for the industry.

Shared Growth Strategy

Mutual

win-win trade

culture

win-win trade

culture

- Maintaining fair and transparent transactions by establishing/notifying Code of Conduct for Partner Companies

- Securing business stability and work quality/safety for business partners by prohibiting low-priced bids

- Appropriate compensation for innovation activities and performance

- Providing mutual technical support and protection of intellectual property rights

- Enforcing the integrity contract with business partners to ensure transparent business management free of corruption

Smooth communication

- Operating the partner company council: Implementing the partner company communication system (difficulties, suggestions, rewards, etc.)

- Operating a procurement portal (Q&A)

A corporate culture that fulfills social responsibility

- Supplier and partner company evaluation reflecting ESG matters(labor, human rights, etc.)

- Complying with laws and regulations

Shared Growth with Partners

Supporting sustainability enhancement

As the necessity of responsible supply chain management for businesses grows, DL Chemical is investing heavily in win-win collaboration with business partners across the supply chain, including management, safety, and quality control.

To increase partner organizations' competitiveness and reduce risks, our standardized safety, environmental, and health criteria are connected to the contract to encourage voluntary participation.

To increase partner organizations' competitiveness and reduce risks, our standardized safety, environmental, and health criteria are connected to the contract to encourage voluntary participation.

Shared Growth Program

Inspecting technical support

Every quarter, DL Chemical conducts technical support inspections to improve partner companies' safety, health, and environmental management.

Education management, safety, and health management rules, work process management, various qualifications management, workplace machinery and tools protection management, and site/machinery and tools checklist management are all inspection elements. Following the inspection, we assist our suppliers in strengthening their capabilities by identifying and strengthening improvement initiatives.

Education management, safety, and health management rules, work process management, various qualifications management, workplace machinery and tools protection management, and site/machinery and tools checklist management are all inspection elements. Following the inspection, we assist our suppliers in strengthening their capabilities by identifying and strengthening improvement initiatives.

Supporting minimization of transaction costs

DL Chemical pays in full in cash within 15 days after completion of the work to prevent suppliers’ poor financial condition. We assist partner companies with their financial soundness.

Additionally, we reduce the cost burden on our partners by promptly reflecting the purchase unit price related to the price of raw materials for items. Furthermore, by subsidizing the KOSHA registration price, we assist local enterprises in managing safety and health in a systematic and efficient manner (KOSHA). We will continue to expand our initiatives to provide financial support to suppliers including exempting the submission of Performance Guarantee Certificates and setting support conditions while continuously finding ways to promote transaction cost minimization.

Additionally, we reduce the cost burden on our partners by promptly reflecting the purchase unit price related to the price of raw materials for items. Furthermore, by subsidizing the KOSHA registration price, we assist local enterprises in managing safety and health in a systematic and efficient manner (KOSHA). We will continue to expand our initiatives to provide financial support to suppliers including exempting the submission of Performance Guarantee Certificates and setting support conditions while continuously finding ways to promote transaction cost minimization.

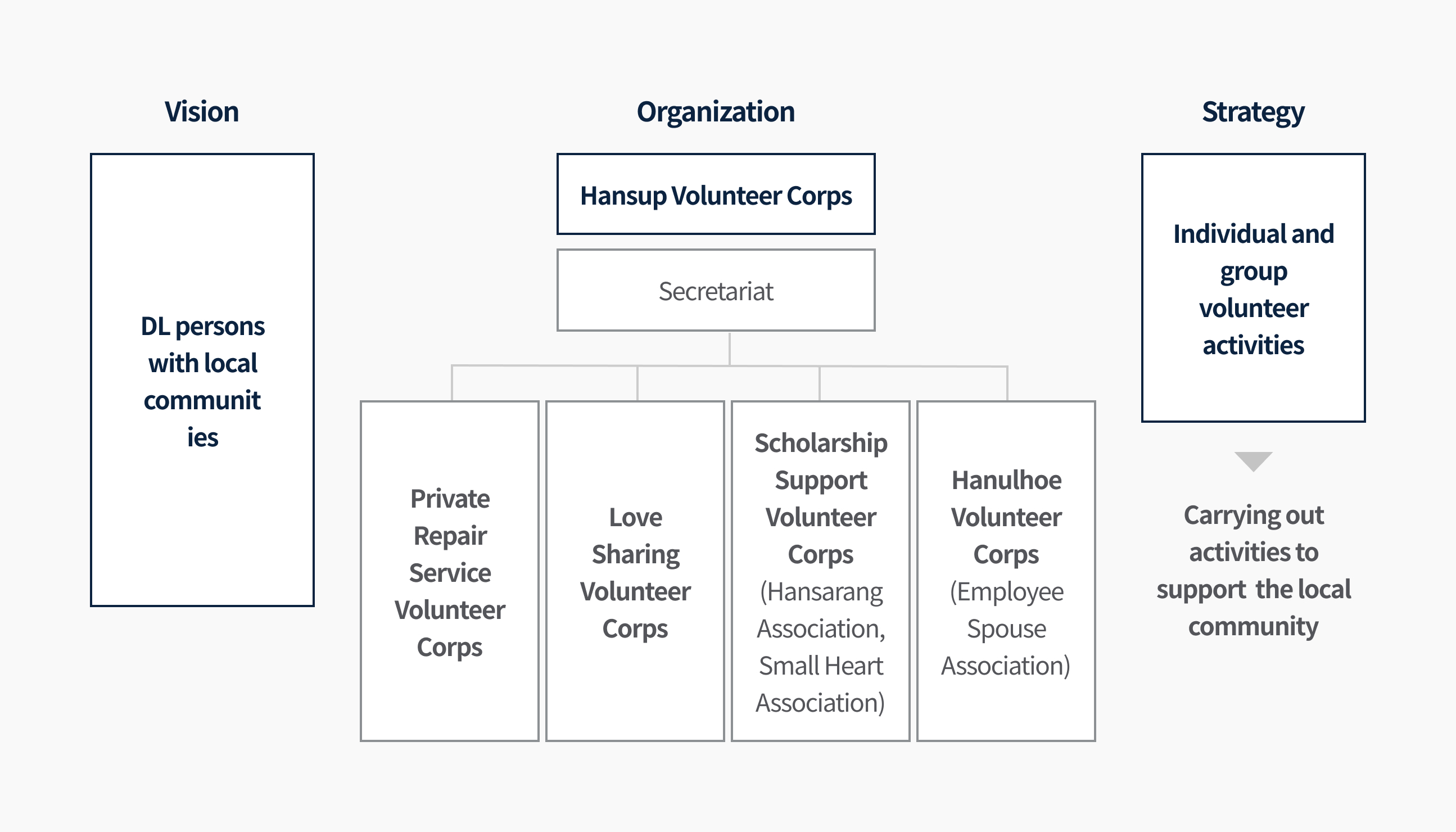

Social Contributions

DL Chemical has established the management principles of respect for human beings, customer trust, and future creation to achieve a comfortable and productive existence. To become a DL person in the local community, we broke away from the old volunteer group-based service approach in September 2004 and founded the Hansup Volunteer Corps, in which all executives and workers join and conduct systematic social contribution activities.